Overview and Applications of Investment Casting

Investment casting, also known as lost-wax casting or precision casting, is an ancient metal forming technique that uses wax patterns to create complex metal parts. This method dates back to around 4000 BC, where ancient Egyptians and Chinese used it to produce jewelry and other intricate artifacts. With the advent of the Industrial Revolution and technological advancements, investment casting has evolved into an essential part of modern manufacturing, widely applied in industries such as aerospace, automotive, medical devices, and jewelry.

Process Flow

Mold Design and Fabrication: The first step involves creating precise molds based on product design drawings. These molds are typically made from high-temperature resistant materials to withstand subsequent heating processes.

Wax Pattern Making: Molten wax is injected into the mold and allowed to cool, forming the desired shape. This stage may require multiple trials to achieve optimal results.

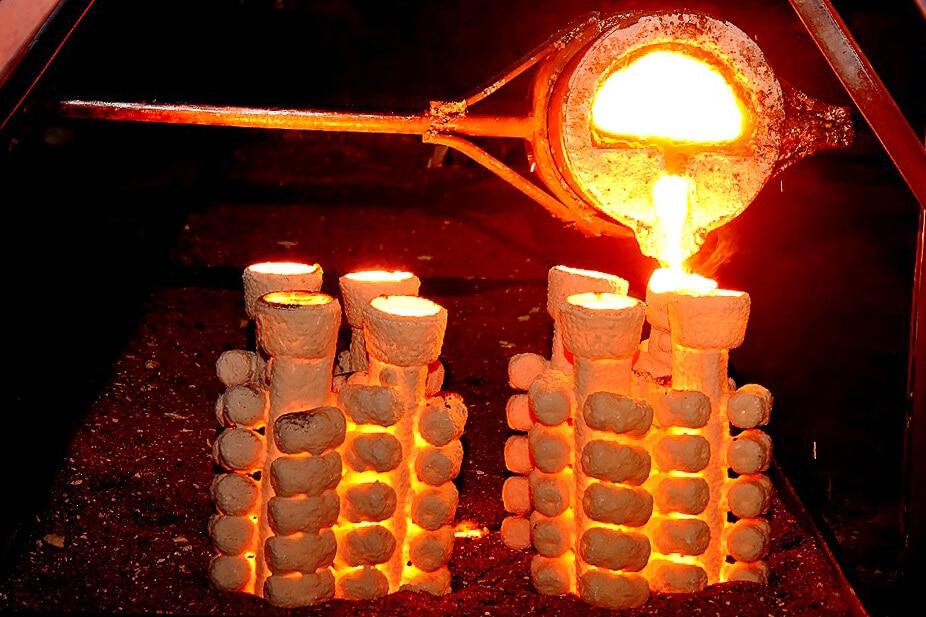

Pattern Assembly: Multiple wax patterns are connected together to form a "tree-like structure," facilitating subsequent processing.

Shell Formation: The assembled wax pattern is dipped into a specialized ceramic slurry and coated with fine sand. This step is repeated several times until a sufficiently thick shell is formed.

Dewaxing and Firing: Heating causes the internal wax to melt and flow out, leaving behind an empty ceramic shell. The shell is then fired at high temperatures to increase its strength.

Pouring: Molten metal is poured into the preheated ceramic shell, filling all spaces. Once the metal solidifies, the shell is broken off to reveal the finished component.

Post-processing: This includes removing gates, polishing, and ensuring the final product meets quality and dimensional requirements.

Advantages and Challenges

High Precision: Using detailed wax patterns allows for the production of highly complex and smooth-surfaced parts.

Wide Material Selection: Almost all castable alloys can be processed using investment casting.

Cost-effective: For small batch production or products with high customization needs, investment casting offers significant cost advantages.

However, investment casting also faces challenges such as longer preparation times, higher costs, and higher skill requirements for operators. Additionally, improper control can lead to defects like porosity and cracks.

Applications and Developments of Investment Casting in Modern Manufacturing

Investment casting is a highly flexible and precise manufacturing technology that plays a crucial role in modern industry. It not only meets the needs of traditional sectors but also shows great potential in high-tech fields. Here are some specific applications and development trends:

Aerospace

The aerospace industry is one of the most important application areas for investment casting. Many critical components, such as engine blades and turbine discs, rely on investment casting to achieve high strength, lightweight, and heat resistance. By continuously optimizing material formulations and process parameters, manufacturers can ensure performance while reducing production costs.

Medical Devices

With the rise of personalized medicine, investment casting is increasingly used in the medical device sector. Customized orthopedic implants, dental implants, and other devices require this technology to precisely match patients' anatomical structures. Moreover, the development of biocompatible materials offers more possibilities for such applications.

Automotive Manufacturing

While the automotive industry often prefers efficient production methods like die casting or stamping, investment casting remains indispensable for certain specialized components, such as exhaust system parts. It helps designers achieve more complex designs while maintaining good mechanical properties.

Development Trends

Digital Transformation: The widespread adoption of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems is making the entire investment casting process more automated and intelligent. This not only improves efficiency but also helps reduce human errors.

Enhanced Environmental Awareness: In response to growing environmental concerns, more companies are focusing on how to minimize waste generation and improve resource utilization. As a result, developing new eco-friendly materials and recycling technologies has become a research hotspot.

Exploration of New Materials: Beyond traditional metal alloys, researchers are actively exploring the investment casting possibilities of composite materials, ceramic matrix composites, and other novel materials. The goal is to expand application ranges and meet higher performance demands.

In summary, investment casting continues to play an irreplaceable role in various industries due to its unique advantages. As technology advances and market needs evolve, this ancient yet advanced manufacturing technique will continue to demonstrate new vitality.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness