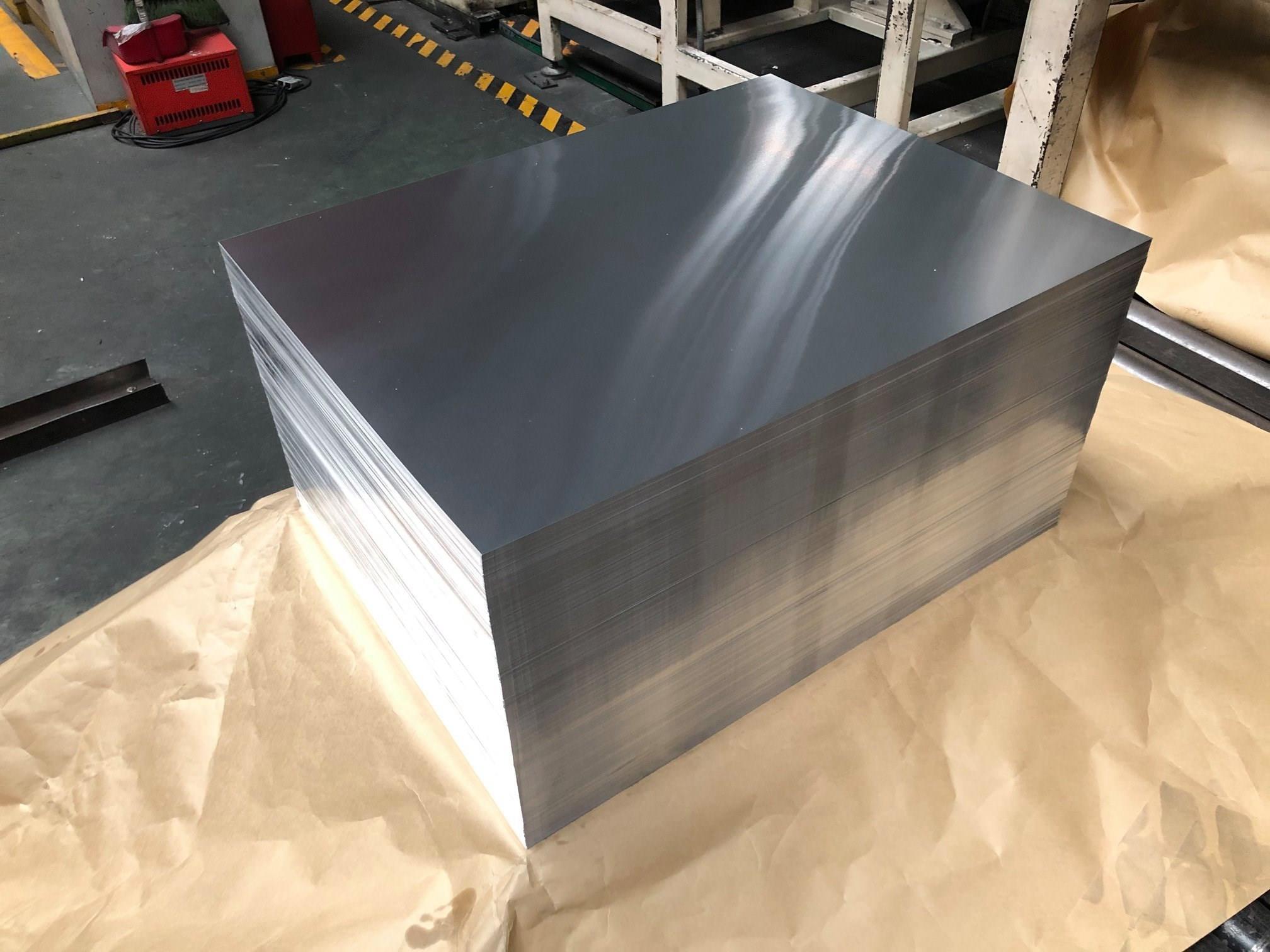

9 Gauge Aluminum

Aluminum is a widely used metal due to its numerous benefits, including lightweight, corrosion resistance, and excellent conductivity. The gauge system is commonly used to measure the thickness of aluminum sheets. A 9 gauge aluminum sheet thickness refers to a specific thickness range within this system. Let's delve into a detailed introduction to 9 gauge aluminum sheet.

-

Gauge System:

The gauge system determines the thickness of metal sheets, including aluminum. It's a measurement system that assigns a numerical value to the thickness of a sheet. A lower gauge number indicates a thicker sheet, while a higher gauge number represents a thinner sheet. -

Aluminum Sheet Thickness:

The thickness of aluminum sheets can vary widely depending on the intended application. In the gauge system, the thickness of aluminum sheets is typically measured in decimal fractions of an inch or in millimeters. -

9 Gauge Aluminum Sheet:

A 9 gauge aluminum sheet corresponds to a specific thickness range. However, it's important to note that the gauge system can vary slightly between different countries and industries. In general, a 9 gauge aluminum sheet is approximately 0.1144 inches thick or 2.91 millimeters. -

Common Uses:

Aluminum sheets, including 9 gauge sheets, find applications in various industries and sectors. Some common uses include:- Automotive: Aluminum sheets are used in the manufacturing of automobile body panels, hoods, roofs, and structural components due to their lightweight nature and corrosion resistance.

- Construction: Aluminum sheets are utilized in construction projects for roofing, siding, facades, and interior design elements.

- Aerospace: The aerospace industry employs aluminum sheets for aircraft components, including wings, fuselages, and interior structural parts.

- Manufacturing: Aluminum sheets are utilized in the fabrication of appliances, containers, signage, and electrical enclosures, among other items.

- Marine: Aluminum sheets are used in boat building and marine applications due to their resistance to saltwater corrosion.

-

Alloy Types:

Aluminum sheets can be made from various aluminum alloys, each offering specific properties suitable for different applications. Common alloy series for sheets include 1xxx, 3xxx, 5xxx, and 6xxx. These alloys possess different characteristics such as strength, formability, weldability, and corrosion resistance. -

Surface Treatments:

Aluminum sheets can undergo surface treatments to enhance their appearance or performance. Some common treatments include anodizing, which forms a protective oxide layer, and painting or powder coating, which adds color and provides additional protection against corrosion.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness