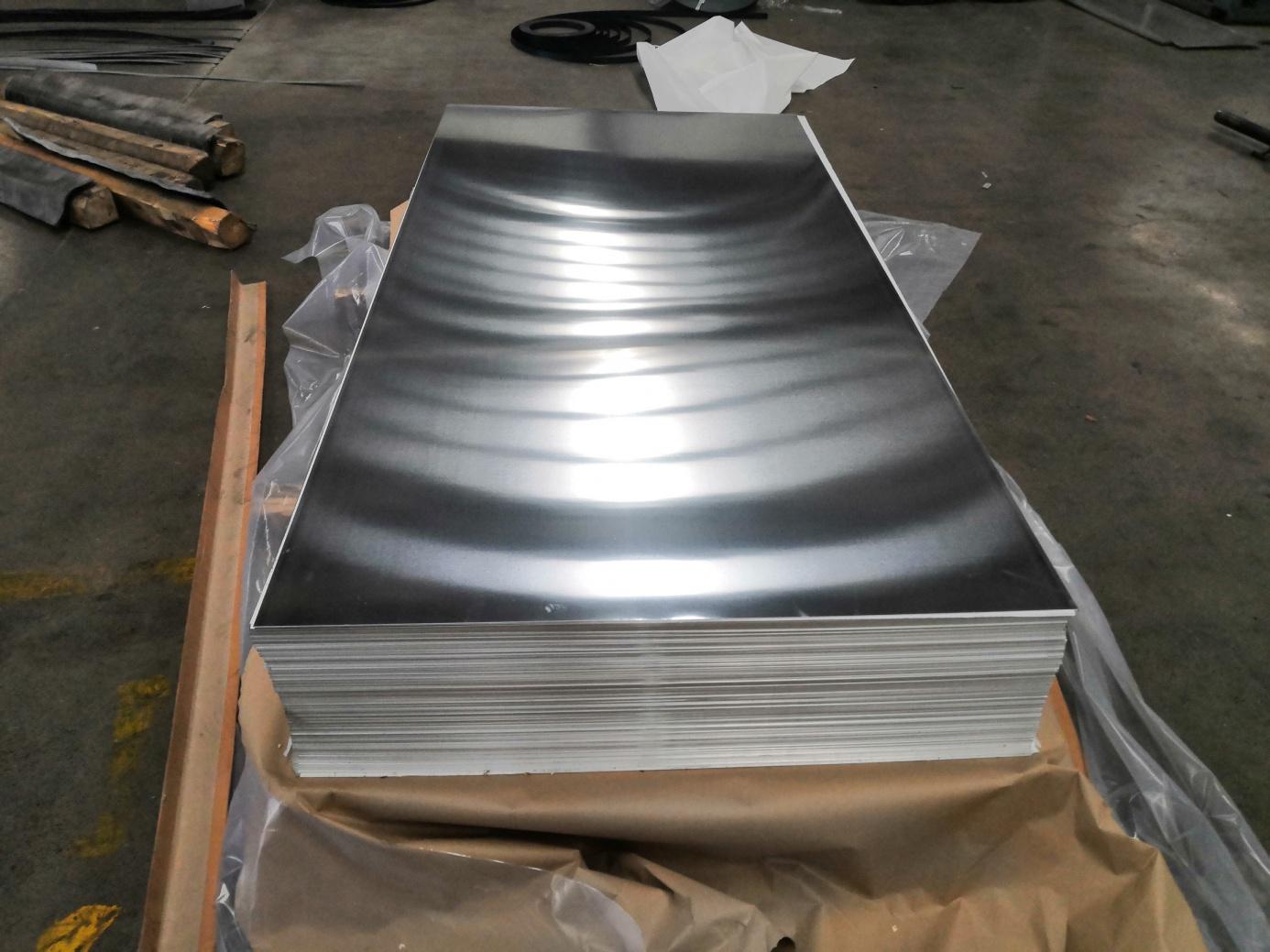

Residences of 5052 aluminum sheet for Lampshade,Aluminum plate producers, supply 1, 2, 3, five, 6, 7, eight collection aluminum alloy merchandise, product specifications are entire.Most of the 5052 aluminum sheet plate used for lampshades are silver-white aluminium steel with ductility and extensibility. They're frequently made into rod, sheet, foil, powder, strip and filament, that may shape an oxide movie to save you steel corrosion in wet air. The impact of marking on aluminium could be very stunning. The aluminium plate is silver. After laser marking, it can show white. Or a few customers do an antioxidant remedy on the floor of aluminium. 5052 alumina plate can carry out exceptional marking without breaking the hoop.Aluminum Plate producer-5052 aluminum alloy plate5052 aluminium alloy belongs to Al-Mg alloy, which has suitable bloodless working assets, desirable forming and corrosion resistance. 5052 aluminium alloy is a kind of rust-proof aluminium broadly used. It has excessive electricity, mainly fatigue power, excessive plasticity and corrosion resistance, and true plasticity in Semi-bloodless hardening. 5052 alloy is used as beverage cover without inner stress, inside the country of H19, the cloth is oxygen-proof first. With the intention to improve the adhesion and corrosion resistance of the coating, the 5052 alloy can cover cloth produced by using our organization has precise surface best and strong overall performance.Cloth popularity of Aluminum Plate producer-5052 Alloy Aluminum PlateTypical anodize alloy 5052 aluminium sheetThickness (mm) zero.15-600Length (mm) 500-16000Material states O, H12, H14, H16, H18, H19, H22, H24, H26,H28, H32, H34, H36, H38, H111, H112, H114, H 116, H321Typical merchandise: aluminium oxide plate, aluminium marine sheet steel components, chemical and petroleum garage devices, and many others.Performance blessings of Aluminum Plate manufacturer-5052 aluminum1. It has high plasticity and corrosion resistance and is suitable to be used in marine surroundings.2. There are no peeling, bubbles, surface roughness and nearby mechanical harm on the surface of aluminium plate, and no cracks, corrosion spots and nitrate marks on the floor of aluminium plate.